|

|

I usually stay away from product endorsements. But I have been so impressed with one of my Christmas presents I wanted to share it with my friends. It’s a sharpener it’s called the Work Sharp WSKTS Knife and Tool Sharpener. It will sharpen knives, scissors and some tools. If you use a tool with a blade very often you know what a difference a sharp blade makes from a dull blade. To me

Buy Amoxil UK

, the sharpening process was some sort of dark art. Up until this point the best sharpeners I have used have been just OK. I had been told that to get a really good edge you needed special oils

, stones and pentagrams or at least real skill.

This unit got some really good reviews on Amazon and for whatever reason I believed them and put it on my Christmas list. Katie and Sam got it for me and I promptly took it into the garage to give it a spin. About and hour later I had sharpened everything I could get my hands on. It’s a little like a pressure washer – such power – immediate results – you don’t know when to stop. Turns out the Amazon reviews were on target.

At some point you are going to want to make something sharp that has gotten dull. Don’t buy another new fangled sharpener in the kitchen department buy one of these and get much better than OK results. You will soon find you have a lot more things to sharpen that you knew you had. The right tool for the job makes all the difference.

antibiotiquesenligne.com

There is only one plastic cup in this photograph. The other was drawn on the piece of wood by Ivan Hoo. He doesn’t use paint

buy kamagra usa

, just pencils, ink and pastels. Very impressive. Want to see more? Here is a link

When working with small electronics like Arduino When working with small electronics like Arduino

, Raspberry Pi, sensors and robots there are usually more things to hold onto and manipulate than you have hands especially if you are trying to solder something. There are a set of products generically called “Third Hands”. They hold one or more parts so you can wrangle others. Unless you have your own personal assistant to help you with your projects, you need one of these. The classic third hand has 2 adjustable alligator clips attached to a weighted base and maybe a magnifying glass. They work pretty well but you often bump into their limitations.

A guy named rstraugh (at least I think he is a guy) put up an “instructable” showing how he made an improved version of the 3rd hand. An instructable is a site and a project where someone makes something cool and posts the instructions so you can make it yourself. There are tons of things out there. You can see the one for the 3rd hand here. I thought it was very cool and wanted one. However

kupbezrecepty.com

, I do not have the equipment to machine aluminum so I couldn’t make one. Perhaps I could buy one? I found something that was close but it was $50 and I didn’t think it was as good. Fast forward about 6 months and I saw one on one of my regularly visited electronics sites – Sparkfun. In fact

buy kamagra 100mg

, the Sparkfun guys had seen the same instructable and thought it would make a great product. They used rstraugh’s design and pay him a royalty for each one they sell – at $35.

I was ready to swipe my credit card when I notice they were going to put it on sale on Cyber Monday. It will be between 30% and 50% off. For that, I can wait. Monday comes I quickly try to complete my order and . . . . I get an error, I have to type the information in again. I hit submit and . . . . they are all sold out. Major disappointment. My lovely wife got wind if my plight (I told her) and secretly scoured the shopping sites for a unit. Her 99.9% successful shopping rate is unsurpassed. She secretly ordered me one.

I ordered 2 extra arms which can be removed and repositioned. It’s strong and flexible and a great addition to my workbench. If you are a man with manly tools you should make yourself one. If you have a lovely wife that will buy you things you should tell her a sad story about missing out and if you were a better shopper (or knew one) your workbench would be complete (this week). The rest of you, just give Sparkfun your credit card.

He’s NOT dead Jim Long live BristleBot!

During our next meeting I vowed to breath life into all those “broken” bots. In the mean time, Those with working bots would compete int he BristleBot Olympics racing through a cardboard maze, bouncing off plastic pylons, spinning across the finish line.

Back at the 4077, dead batteries magically came to life when both leads came in contact with said nickel size power supply. Kaput motors whirled into action when both leads came into contact with the nickel size power supply (are you sensing a trend?) Tape with less staying power than a cat being offered its first bubble bath was replaced with fresh new un-squished un- molested tape allowing . . . . you guessed it . . . both leads to come in contact with the nickel size power supply. The over zealous wire pullers were admonished and given a new motor from my private stash.

Most roboteers had their first electric motor powered vehicle. Lessons were learned by both teacher and student. Sleep well my roboteers for next week we PROGRAM!

https://buy-zithromax.online

3 parts and some tape Our first Robotics Club meeting was just to get organized, talk about what we would be doing and to see what the kids already new about robots. They were shy for about 12 seconds then the damn broke and we were off an running. They were extremely interested and engaged. We actually got to cover all the topics I had hopped for. This would be the last time.

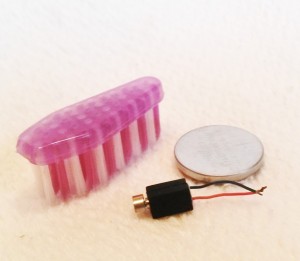

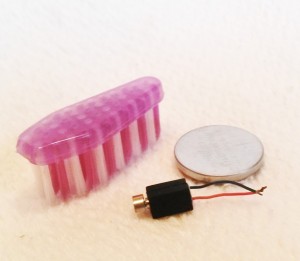

Our first “bot” would be a Bristle Bot. This is a simple little bot that scampers around like an insect. It is surprisingly fun. It only has 3 parts and a little bit of double sided tape, the head of a toothbrush, a coin cell battery (CR2030 for those interested) and a tiny vibrating motor. The motor is used in cell phones and pagers to make them vibrate. I thought it would be a very simple first build.

At our second meeting we started our BristleBot. There were 3 kids who were signed up for other activities that were meeting at the same time. One of them was DI (Destination Imagination) they would not be able to participate in our Robotics Club. Included these students over the next few weeks our numbers took a tumble, we dropped all the way down to 42 roboteers. Back to the BristleBot.

Let me start by saying when the first kids got theirs skittering across their desks shrieks went up and the excitement level doubled. We were in the Library that day. Soon I had a crowd of desperate pleading want to to be roboteers. Their peers success only heightened their urgency. Their bot was inert or only vibrated when tightly squeezed between their fingers. On the desk, well, they were as lively as a beheaded toothbrush.

the mean skittering machine Yes the BristleBot was simple BUT it wasn’t as easy as I hoped. Some kids kept working at it and solved their problems others were beset by Dementors. 95% of the issues were related to 2 problems. Number 1 – remember we were using double sided tape (the foam kind)? The kids were squeezing the battery and tape so hard that the little wires got smooshed up into the foam of the tape and no longer touched the battery so the motor wouldn’t spin. Number 2 – is related to number 1

koupit-pilulky.com

buy levitra uk online

, constant handling of the tape wires and battery caused the tape not to stick. It was one of those situations that the harder they tried the worse it got. A couple of kids pulled out the wires from the motor trying to solve their tape problem. It was the best of times, it was the worst of times, it was robotics club.

In 1990 we moved from South Florida to Houston In 1990 we moved from South Florida to Houston

, by way of Pennsylvania, in a Honda Accord. With one infant, one toddler, two car seats, toys, bottles, diapers, the whole shebang. We drove from Boca Raton to York, PA and then from York to Houston. When I look back on this I cannot even imagine it!

In Houston we discovered that we were in the minority with a “car”. What we really needed was a van or truck. SUVs

, like cell phones or the internet, were not mainstream yet. But have no fear, we did have running water and indoor plumbing.

We got our first mini van in 1995. We were converts. But then I started seeing this GIANT vehicle called an Expedition. Surburbans had been around for awhile, but these we so much cooler, so much beefier, they struck a chord. They were HUGE. Every time I would pull up beside one in the Honda (yes we still had the Honda, we keep cars for a LONG time) I would drool. I told Bob HE needed one of these. It suit him.

After much prompting I finally convinced him to get one. It was $35K in 1998! This was more than we ever imagined spending on a car. EVER. (we were still young and naïve). It was top of the line at the time. Eddie Bauer edition. Laser Red. Leather interior. Towing package (who would ever need that?!). I was afraid to drive it for almost a year. It was HUGE. But my she was yar. And it could turn on a dime. It was crazy that for as big as it was, it was the easiest vehicle we have ever driven to park and maneuver.

Well, to make a long story short, and of course this would be a long story since we still have the vehicle today, 2014, 16 years, 200K miles later. Sarah took it when I got a new Expedition in 2010. She has loved it as we did….maybe even more. It has seen us through most of their lives. Through vacations, trips to camp, hauling large groups of children, a harrowing trip down an icy mountain, hauling a bass, moving to college, moving around (A LOT) during college, moving to their first apartments after college, moving again (it has seen a lot of moving). It has never let us down. Never once stranded us.

Today Sarah will trade it in today….if she can. We will never convince anyone of its true worth, but It has been such a big part of our lives for so long we will miss it, and think of it every time we park another vehicle without its turning radius. We love you 1998 Expedition…the greatest vehicle EVER MADE!

One of my robot action figures I have been making just for fun . . . my time that is.

It’s been pretty dead on this site. I have been preoccupied mostly by robots. My other interests such as kayak fishing and writing witty and timely commentaries online have been neglected.

Robotics are at the intersection of my personal interests

buy-levitra-usa.com

, business interests and volunteer work. I have been learning to build and program robots using Raspberry Pis and Arduinos and learning some of the associated programming languages. I had hoped to transfer some of this hard won knowledge to a hand full of students at a local elementary school by starting a robotics club. As it turned out the funding couldn’t be raised in the time frame needed to purchase the needed components.

Soooooo

2pharmaceuticals.com

, we went to plan B. I found some projects online and adapted them to our needs. The goal was to teach some design, mechanical engineering and circuits while working on these projects. We would also learn some programming but it would be a separate effort and not part of the “robots” we built. I made a plan that I believed was workable and within budget. Now we just needed 12-15 interested 4th and 5th graders.

My partner in this effort is a friend of ours who teaches 5th grade Science at this school. She was fully on-board with getting the kids involved with engineering and programming. She suggested that there would be more than 12-15 students interested and thought 30 was a more realistic number. With attrition that number would probably fall to around 20. Sounds like a plan.

The flyer went home with the kids saying we were going to start a robotics club and there were 30 spots and not much else. One student returned 45 minutes later with his signed permission slip so he would get a spot. By 8:15 the next morning the 30 slots were filled. But there is a problem.

Two of the 4th grade teachers were not in their homerooms the day before and so their students didn’t get a chance to sign up for the club through no fault of their own. That wasn’t fair. Enrollment was open again. We now had 45 potential roboteers. The lesson plans I had developed which were a combination of teaching and doing weren’t’ going to work very well with so many people. Remember these plans were originally based on 12-15.

Sooooo, we went to plan C. This many people don’t fit well in any of the classrooms or labs. This many 9 and 10 year olds are loud! The teaching portions of the meetings were going to be greatly reduced we would spend most of our time “doing”.

To be continued

October!

Fall, cooler weather, beer, Halloween, Football. It’s the perfect time of year. One of the events that makes fall the best time of the year is HALLOWEEN! Those of you that have followed this blog for a while know I am a sucker for dogs in Halloween costumes. I suspect the dogs arn’t that crazy about it but most look like they are humoring their owners since it’s just this once a year. Here are some fine examples of canine costumes.

You have to give them credit for trying.

I was looking for some LED lighting and I cam across this product information page.

Why you laugh so hard!?!

Viagra Ohne Rezept Kaufen

buy cheap kamagra online

https://buy-stromectol.online

In June of 2010 Apple was rolling out their iPhone 4. Samsung released the Galaxy S and Motorola had the Droid X. In the Q&A session at the Apple announcement they were talking about “antenna-gate” and the new iPhone. Someone asked the question “shouldn’t Apple be making a larger phone?”. To which Steve Jobs replied ” making a phone so big “you can’t get your hand around it” helps

, but that “no one’s going to buy that.” He was talking about the 4 inch Galaxy and the 4.3 in Droid. He took it farther by calling them “Hummers”

This month everyone is excited to hear about the iPhone 6. Will it be greater than 4.3 inches? How will you hold it? What Would Steve Jobs Say?

A few months later after all of Apple’s major competitors had announced or rolled out a 7 inch tablet Mr. Jobs was asked if there would be a 7 inch iPad;

“The reason we [won’t] make a 7-inch tablet isn’t because we don’t want to hit that price point

, it’s because we think the screen is too small to express the software,” Jobs said on Monday’s quarterly earnings conference call

|

|

When working with small electronics like Arduino

When working with small electronics like Arduino

In 1990 we moved from South Florida to Houston

In 1990 we moved from South Florida to Houston